Our Product Engineering Center is an independent factory with the complete and systematic toy production flow, the engineering core of our company and the engineering base for designing and developing new products. It can also undertake manufacturing and processing of new products and moulds of smaller quantity in the experimental stage.

The center is complete in equipment and department and has a powerful technical team composed of managing engineering and technical personnel, which can guarantee efficient support, communication and production.

Production flow:

Ⅰ Prototype design, development and making

The professional prototype workshop can provide the following services:

Making clay prototypes of various cartoon figures, animals, insects and portraits of varieties;

Design, making and upgrading of action models such as car and building models and enclosures;

Making models of emulational cars professionally;

Prototype Enlargement and Deflation;

Mould pickling, enlarging and detachment.

Ⅱ Prototype Confirmation & Mould Design

When the prototype is confirmed by the customer, we will carry out mould design. Reasonable mould processing method and mould structure can not only decide production efficiency (turnover) and cost but influence directly the quality and appearance of finished products. Our mould design team owns a dozen professional design engineers, who can make reasonable arrangement, selection and design on parting line, internal mould processing method, material chosen and mould structure and guarantee the production efficiency and quality.

Ⅲ Beryllium -- copper mould and steel die casting ( precise copy—one of the internal mould processing methods)

This internal mould processing method focuses on products with fine pattern, complicated form, irregularity and short turnover.

Beryllium copper mould

The Beryllium copper mould cast with the ceramic casting techniques shares the following merits:

Finer than that made with the traditional sand mould casting method; obvious improvement for mold distortion.

Cleaner and brighter surface; polishing procedure saving

Precise dimension; cavity processing saving

Little distortion; precise product quality guarantee

High erosion resistance

High intensity (98-116KGF/M 2); high rigidity, possible to reach HRC30 ° -45 ° after hardening solution

Easier to cool down; one third off for the injection molding period; shortened productive man-hour

Steel die

Our mould casting technicians possess the mould casting experience of 15 years and are able to cast steel die l ike 718, 738, 136 and 8407. Our steel dies share the following merits:

Cleaner and brighter surface; high precision; little deformation

S136H steel die features excellent polishing performance and rust prevention ; applicable to transparent products and PVC products

Convenient for maintenance; shorten mould making time due to the adoption of casting mold and lower mould cost

Ⅳ Carving

Our powerful Carving department can provide service of en graving not only for casting mould internally but also for clients.

12 sets of imported Carving machines; a team of elites in design, sample making and CarvingBright, precise, exact internal mould Carving

Clear and precise Carving for precise 3D Electrode

Tiny clip line; guaranteeing the quality of finished products in all sides

Ⅴ CNC Processing Center

Our modern CNC Processing Center focuses on mould processing for king-size products and parts that have regular shapes.

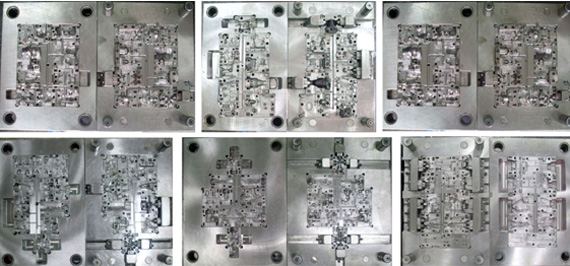

Ⅵ Mould

Our well-equipped factory boasts the Prototype Department, Sample Making Department, Casting Department, Carving Department, Spark Machining Department and CNC Processing Department. Different products can adopt their corresponding internal mould processing methods, which surely guarantee mould making in time and quality. A complete set of facilities and close link-up of work procedures herald the easy completion of the whole course from design to production for clients.

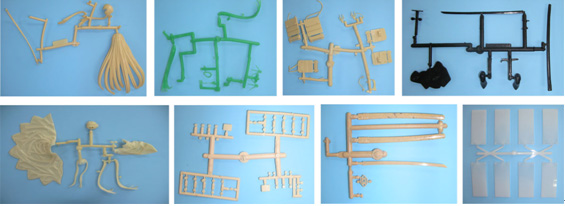

Ⅶ Injection Moulding

The injection moulding workshop for mould trial, production and processing is available in our factory.

Ⅷ Sample Fabrication

Ⅸ Production & Document Follow-up

Our production and document engineering will handle the design and arrangement on production and processing detail, key production line reasonably and neaten the complete document engineering material to carry out production document follow-up in the produ.

CopyRight Shenzhen Dianman Plastic Toys Co.,Ltd. Tel:0755-28688552 Address:Building 20,Second Distric,JiaDeMaLuan Industrial Park,Tangkeng Road,Pingshan New Distric,Shenzhen City,Guangdong Province.

Fax:0755-28688502 Email:dm@szdmtoys.com Website: http://www.szdmtoys.com